The first mention of the Broadway Pottery was in a document dated 1890, however local historians don’t know much about the pottery before the early 1900’s when a young man named Charles (C.C.) Wood began working there.

Wood enjoyed the pottery business — creating, firing and finishing fine earthenware, but eventually the salary he was able to draw from working there was not enough to support his growing family. He accepted a job at a large pottery in Keyser, West Virginia. While the Wood family was in Keyser, the Broadway Pottery closed.

In 1925, C.C. and his family returned to Broadway, and together with his wife, Lena, and fellow potter, Fred Byford, they formed a corporation and bought the Broadway Pottery. They changed its name to Shenandoah Pottery Company.

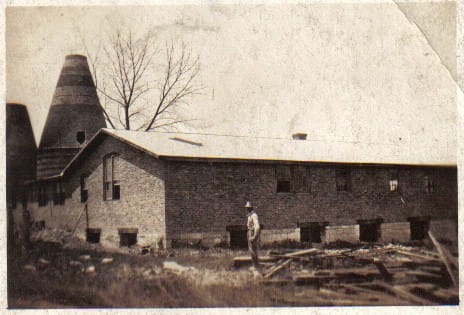

About ten years ago, we were able to talk with Harold Wood, C.C.’s son, about what it was like growing up around the kilns and clay. Many of Harold’s earliest memories were centered around the family’s business. He remembered playing around the big kilns and watching the pottery being created. The the main floor of the building held supplies such as silica rock, sand, kaolin clay, fire clay and other minerals. The pottery did not use local clay, but ordered the raw materials elsewhere.

The main floor also held tons of coal needed to run the huge kilns. The kiln temperature had to be exact in order for the pieces to come out without cracks and blemishes. Pieces had to be in the oven for three days in order for the glaze to set properly. After the three day firing period, workers had to wait several days for the large ovens to cool enough to remove the pieces.

All during the firing process, C.C. or one of his employees had to keep the fires burning at an even temperature day and night. They did this by shoveling coal into huge, metal doors located around the base of the kiln.

The Shenandoah Pottery manufactured toilets, sinks, earthenware, porcelain, china, terra cotta, bricks, tiles, pipes and ceramic ware. It also produced glassware, glass ornaments, cut glass and structural glass. The Pottery shipped the finished products by railroad to markets in the northern states.

Unfortunately, the Shenandoah Pottery didn’t survive the economic woes of The Great Depression. Although the pottery has been closed over eight decades, some of the pieces it produced are still collected today.

Information from Local Lore of The Shenandoah (Lilliendahl and Cullers)

Wood enjoyed the pottery business — creating, firing and finishing fine earthenware, but eventually the salary he was able to draw from working there was not enough to support his growing family. He accepted a job at a large pottery in Keyser, West Virginia. While the Wood family was in Keyser, the Broadway Pottery closed.

In 1925, C.C. and his family returned to Broadway, and together with his wife, Lena, and fellow potter, Fred Byford, they formed a corporation and bought the Broadway Pottery. They changed its name to Shenandoah Pottery Company.

About ten years ago, we were able to talk with Harold Wood, C.C.’s son, about what it was like growing up around the kilns and clay. Many of Harold’s earliest memories were centered around the family’s business. He remembered playing around the big kilns and watching the pottery being created. The the main floor of the building held supplies such as silica rock, sand, kaolin clay, fire clay and other minerals. The pottery did not use local clay, but ordered the raw materials elsewhere.

The main floor also held tons of coal needed to run the huge kilns. The kiln temperature had to be exact in order for the pieces to come out without cracks and blemishes. Pieces had to be in the oven for three days in order for the glaze to set properly. After the three day firing period, workers had to wait several days for the large ovens to cool enough to remove the pieces.

All during the firing process, C.C. or one of his employees had to keep the fires burning at an even temperature day and night. They did this by shoveling coal into huge, metal doors located around the base of the kiln.

The Shenandoah Pottery manufactured toilets, sinks, earthenware, porcelain, china, terra cotta, bricks, tiles, pipes and ceramic ware. It also produced glassware, glass ornaments, cut glass and structural glass. The Pottery shipped the finished products by railroad to markets in the northern states.

Unfortunately, the Shenandoah Pottery didn’t survive the economic woes of The Great Depression. Although the pottery has been closed over eight decades, some of the pieces it produced are still collected today.

Information from Local Lore of The Shenandoah (Lilliendahl and Cullers)

RSS Feed

RSS Feed